High-Quality Service

Time & Cost Savings

Committed to Safety

Get a Quote

Thank you for contacting Australian Asset Compliance.

We will get back to you as soon as possible.

Please try again later.

Trusted Compliance Services Across Gympie

Australian Asset Compliance provides reliable asset compliance in Gympie, helping businesses manage safety obligations with less stress. Our services include height safety inspections and pallet racking checks. Each inspection is backed by transparent reporting, giving managers a clear view of what meets compliance standards and what needs attention.

The Gympie region includes a mix of industries, from agriculture and transport to education, retail and manufacturing. Each sector depends on safe equipment and compliant systems to keep staff protected and operations efficient. We also extend our services to surrounding areas such as Tin Can Bay, Maryborough, Cooloola Cove and Rainbow Beach.

For organisations managing multiple sites across South East and Central Queensland, we deliver consistent inspections and practical reporting that save time and reduce risks. With one provider managing multiple compliance needs, businesses can cut costs, avoid scheduling stress and maintain compliance without confusion.

To arrange a service, call us on 1800 870 081.

Frequently Asked Questions

What is the difference between a safety inspection and a safety audit?

A safety inspection involves checking equipment, structures or systems for hazards or non-compliance issues. A safety audit, however, is more comprehensive, where auditors review policies, procedures and management systems alongside inspections. Both play a vital role in maintaining safe workplaces and ensuring organisations meet regulatory and legal obligations.

How can businesses prepare for a compliance inspection?

Preparation involves reviewing equipment records, maintenance logs and previous inspection reports. Businesses should also ensure all areas are accessible and staff are aware of the scheduled inspection. By preparing in advance, organisations streamline the inspection process, reduce disruption and increase the likelihood of achieving positive compliance outcomes.

What are common hazards identified during workplace inspections?

Common hazards identified during workplace inspections often relate to wear, damage or misuse of equipment and safety systems.

In pallet racking, this can include bent uprights, missing safety pins, overloaded beams or poor housekeeping around aisles. For height safety systems, typical issues involve corroded anchor points, loose fittings, damaged harness gear or inadequate access to roof areas.

Inspectors may also find missing load signage, blocked emergency exits or untrained staff using equipment incorrectly. Identifying these hazards early allows businesses to take corrective action before an accident occurs, protecting workers while maintaining compliance with current Australian safety standards.

Pallet Racking in Gympie

Safe racking systems are vital for warehouses, retail outlets and storage facilities. We deliver thorough pallet racking inspections in Gympie to detect damage, overloading or misalignment before accidents occur. Our team clearly outline hazards and provides practical recommendations for corrective action. By booking routine inspections, Gympie businesses protect staff, reduce downtime and extend the life of their storage systems, keeping workplaces safe, compliant and efficient across all operations.

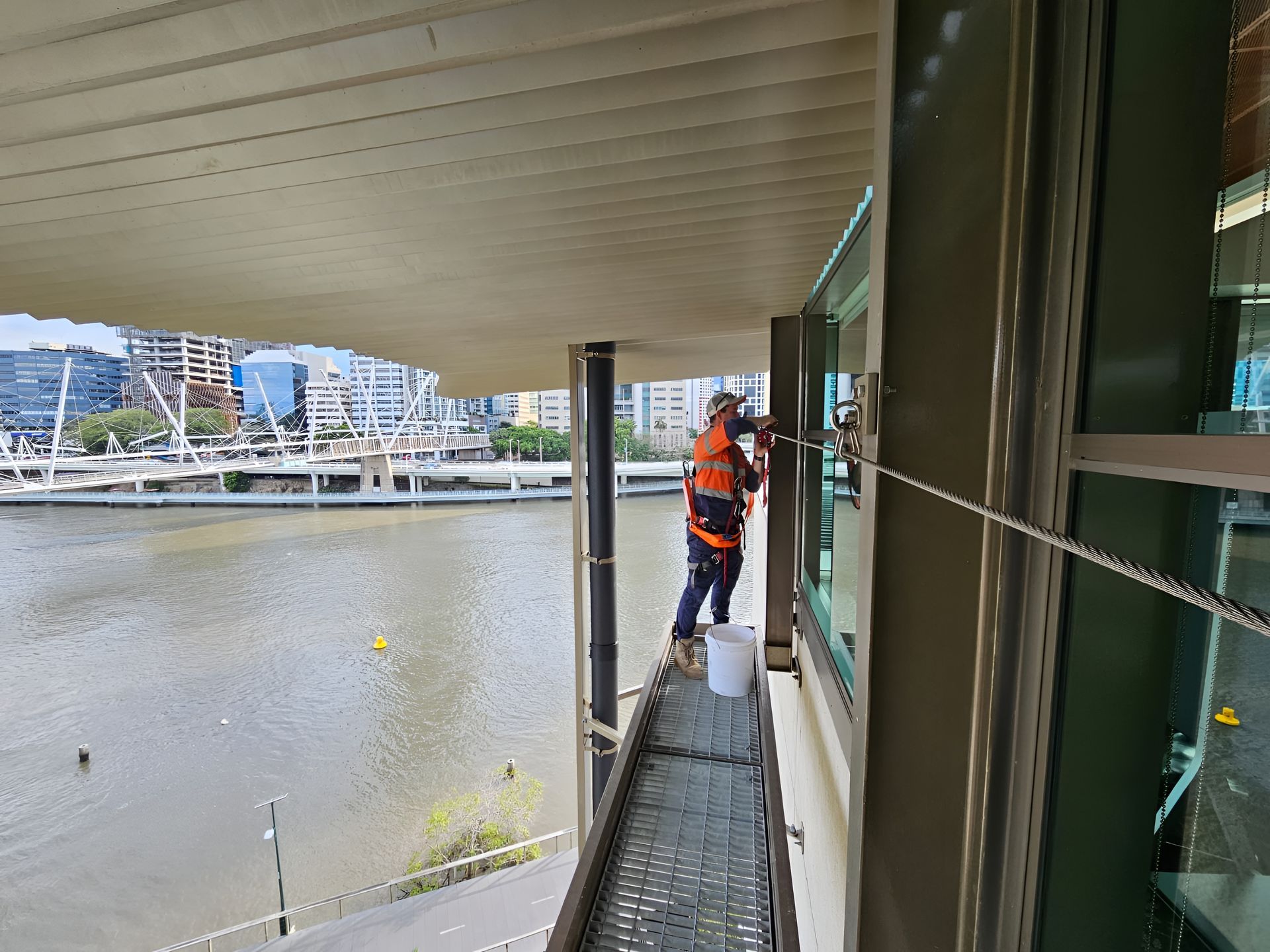

Height Safety in Gympie

Workplaces often have safety equipment that must perform reliably. We provide detailed height safety inspections in Gympie, checking anchor points, ladders, harnesses and static lines against Australian standards. Our team highlights compliant systems and notes issues that require attention. By scheduling regular inspections, local businesses can reduce risks, maintain compliance and protect staff. Reminders and scheduling support make it easier to stay on top of obligations year-round.