High-Quality Service

Time & Cost Savings

Committed to Safety

Get a Quote

Thank you for contacting Australian Asset Compliance.

We will get back to you as soon as possible.

Please try again later.

Comprehensive Compliance Services Across Emerald

Australian Asset Compliance provides dependable asset compliance in Emerald, helping local businesses maintain safe and compliant workplaces. Our services include height safety inspections and pallet racking checks. With clear, transparent reporting, managers can see exactly what meets standards and what needs attention, making compliance easier to manage.

We also support neighbouring areas such as Blackwater, Springsure, Capella and Middlemount. For businesses with multiple sites across Central Queensland, our team delivers consistent inspections and straightforward compliance solutions. This approach saves time, reduces risks and ensures obligations are never missed. Whether you manage a warehouse, oversee properties or maintain community spaces, our services are designed to keep your operations safe and efficient.

Partnering with one provider for multiple compliance needs means fewer disruptions and greater peace of mind. Call 1800 870 081 today to arrange an inspection.

Frequently Asked Questions

What are the main causes of pallet racking damage?

Pallet racking damage is most often caused by forklift collisions, overloading, poor installation or neglected maintenance. Even small dents, loose bolts or missing safety clips can weaken the entire structure and create dangerous conditions for staff. Daily wear and tear also contributes over time. Regular pallet racking inspections in warehouses and distribution centres identify these problems early. They prevent collapse, protect workers and keep storage systems reliable and efficient. Inspections also ensure racking remains fully compliant with Australian standards.

How can I tell if height safety equipment needs replacing?

Height safety equipment, including harnesses, lanyards and anchor points, must be carefully checked for wear and expiry. Signs like frayed straps, rust, corrosion or faded inspection tags mean equipment should be replaced immediately. Damaged or expired gear should never be used, even once, as it puts workers at serious risk. Professional height safety inspections in the workplace confirm if gear is safe, ensuring compliance while keeping employees protected when working at heights.

What are common compliance gaps found during height safety inspections?

Many workplaces fail to maintain current recertification, or they overlook corrosion and loose fittings caused by weather exposure. Others have systems installed years ago that no longer meet updated standards or are incompatible with modern personal protective equipment.

Some sites also neglect to provide easy access for workers, increasing the temptation to bypass safety procedures. Inspections help identify these issues early so upgrades or repairs can be planned before accidents happen. Addressing gaps promptly protects workers and maintains compliance with legal obligations under workplace safety regulations.

Height Safety in Emerald

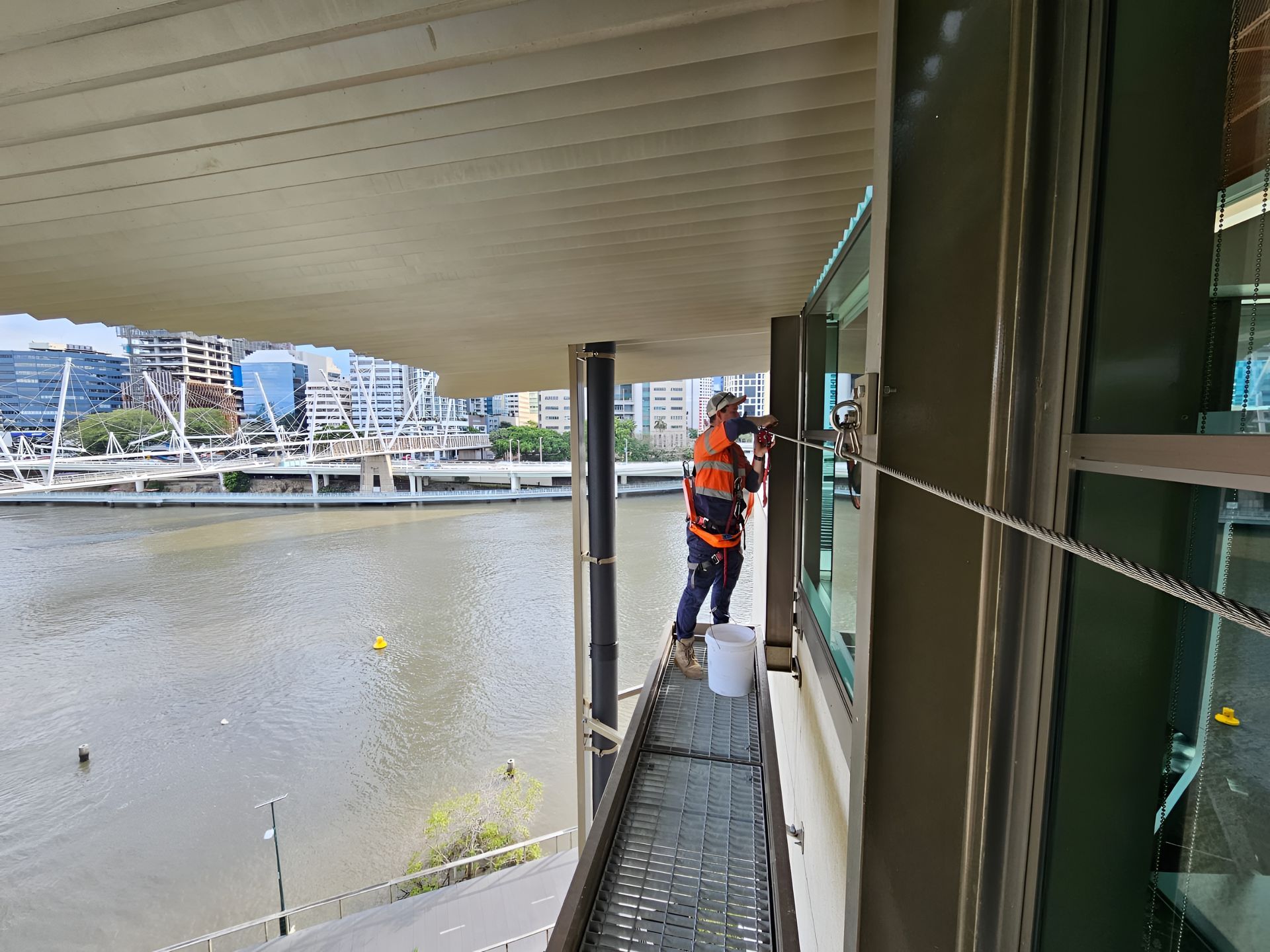

Safe practices at heights are essential across industries in Emerald, from construction to mining and property maintenance. We provide professional height safety inspections in Emerald to ensure equipment and systems meet national standards. Our team checks anchor points, static lines, harnesses and other fall protection gear thoroughly. Reports are clear and practical, showing what is compliant and where improvements are needed. With reminders and scheduling, Emerald businesses stay on track with inspections, protect staff and reduce risks linked to working at heights.

Pallet Racking in Emerald

Warehouses and storage facilities depend on secure racking systems to keep operations safe and efficient. Our team delivers reliable pallet racking inspections in Emerald to identify overloading, structural damage or misalignment. Every inspection comes with a detailed report that highlights issues and recommends corrective actions. By staying proactive, businesses reduce downtime, avoid costly repairs and protect staff from potential hazards. From smaller storerooms to larger distribution centres, we ensure storage systems remain compliant, reliable and safe year-round.